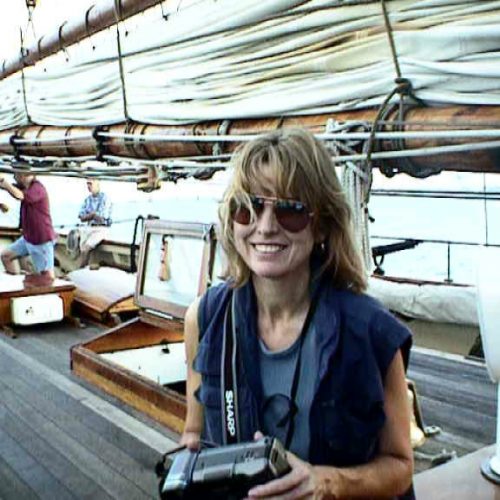

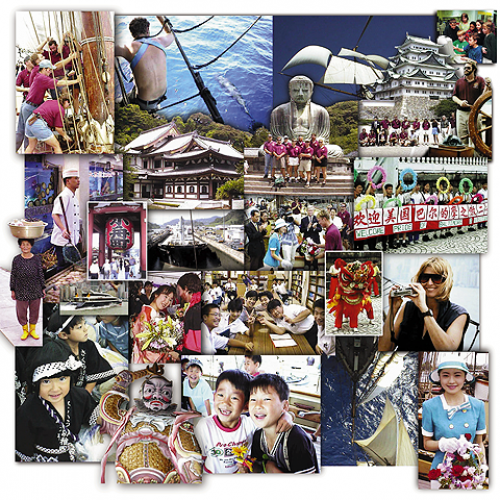

I had sailed with Peter Boudreau on the first Pride of Baltimore, and was his Yard Foreman for the building of the pungy schooner Lady Maryland. So when Peter was awarded the job to build Pride of Baltimore II, he asked me to assist him with the project as the Yard Foreman and invited me to go down to Belize to investigate sources for tropical hardwood to build the new vessel.

I responded to Peter’s invite to Belize with a quick “sure, why not”, it was winter in Baltimore, 1987, with ice and very cold temperatures, so this was an enticing invitation. So we packed up and flew out of a cold BWI to a tropical Belize. Our jet landed at a small airport in Belize with a single runway. As we exited the plane a blast of warm balmy air hit us and flicked a switch in our brains from the cold winter of Baltimore to a new tropical world. The stair ramp from the jet went directly down to the runway where we were stopped by a crossing guard who said we had to wait until another plane which was taxing to roll down the runway and take-off. As we waited, we noticed a military encampment under camouflaged tents just off to side of the runway including a Harrier jet, this was part of a small Great Britain troop contingent present in the country. The terminal at the International airport was a cinder block building without any windows just openings in the block walls. The Customs check was fairly simple compared to current day process. The road leading to and from the airport was a gravel and dirt road.,

Once at our lodging we met up with a junior official from the American Consulate who was a native Belizean. He would be our liaison and facilitate introductions to lumber sources and give us the lay of the land. One of our first meetings was with Loskot Lumber owned by two brothers, one was a Major in the Belize Defense Forces and typically dressed in military fatigues. The lumber company was located along the New River in the Orange Walk district north of Belize City.

We rented a gold Ford LTD which was our source of transportation throughout our travels in Belize. Peter’s brother in-law Andy Miller had joined us for the trip to Belize. As three Americans wearing large brim straw hats driving around in a Ford LTD, I think some people probably mistook our mission as something other than building a boat. In addition, there had been a press release about our mission to build a boat with a large budget to buy lumber, so there were a few hands out trying to sell us many things.

At our meeting with the Loskots at their lumber yard, Peter sat down with one of the brothers in their office which was a simple wood structure with thatched or tin roof. Peter having been involved in the building of the first Pride was already familiar with some of the wood species in the country and had a good idea of some of the specific things needed for the construction.

The Loskots informed us of what species of woods were available, relative cost and logistics of getting the lumber loaded. They suggested we join them on a trip up the New River with their ‘tree hunter’ to their logging camp where they cut the trees and then place in the river as part of a bundled log float which would be towed down the river to the lumber yard for milling.

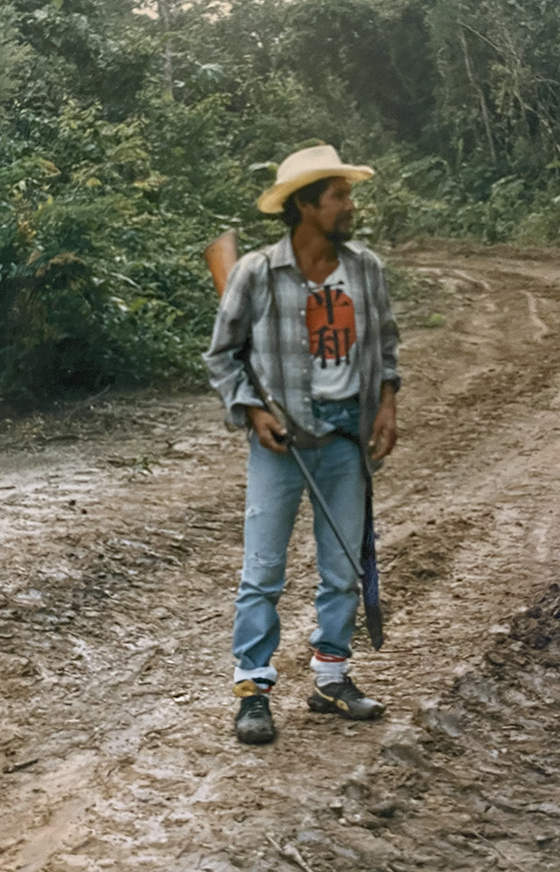

As it turned out the day we were able to take the trip was a Saturday. Their lead ‘tree hunter’ was a Seventh Day Adventist therefore was not available to guide us, so the Loskots found their 2nd tree hunter in a rum shack. He was quite stoned when he joined us at the dock to embark on our boat trip. His English was limited but nevertheless he was quite animated, that being said it was an interesting trip!

This trip really wasn’t necessary since we didn’t actually mark and select the actual trees, it was more of a ‘dog and pony show’. It was a long trip up the river, with forested jungles along most of the river banks, occasionally we saw some mounds up from the banks of the river which apparently were remnants of Mayan structures.

The actual logging camp was located in a small primitive clearing in the jungle with a wood dock, a thatched hut and logs in the water formed into a chain float. As we stepped on land, we quickly realized we were not dressed right for this trip because the trails were muddy with deep ruts created by large equipment skidders pulling trees from the forest, and it had recently rained.

We were being led by the Loskot brother who was a Major and the 2nd tree hunter. As we walked along the trail they told us about the habitat, identified trees and wildlife we might encounter.

The 2nd tree hunter informed us of the ‘medicinal values and benefits’ of many of the plants and nuts growing along the trail. They also said to keep an ear out for animal sounds since there were wild boards and large cats that could attack us.

This is why the 2nd tree hunter was carrying a rifle for our trek. Walking along he would often turn to tell us something, as he did so the gun would be pointing directly at us with his finger near the trigger and he was still quite stoned. Our knee jerk reaction was to duck or step aside for safety, which usually put us in one of the deep ruts of wet mud created by the log skidder. Of course if a wild boar or cat did attack us, we would have been in real trouble because the tree hunter had loaded the wrong ammunition for his rifle which we did not find out until we were back at the main lumber yard.

The excitement didn’t stop there, when we finally were back at the lumber yard dock and were driving back to town with the Loskots in a their Land Rover the rifle barrel was rested on the back of the front seat bench pointing back toward us in the rear seats as we drove over bumpy and rutted roads. There was also a can of gas from the boat in the vehicle and one of the Loskots was smoking a cigarette sitting near the can. Needless to say when we got back to our lodging we were dirty, tired and relieved to be out of harms way!

During our stay we took several road trips in our Ford LTD to different regions of Belize and even took a short detour in Guatemala for part of a day, which had a different feel than Belize. We saw a lot more military and police carrying weapons in Guatemala than Belize.

At one point we stopped into a small country store where we had a brief encounter with a group of 4 Guatemalan police who took an interest in us, they didn’t speak English but Peter understood enough Spanish to have a limited conversation with them and tried to compliment the ranking officer. Andy and I posed in a group photo with them as Peter looked on nervously, having heard some of their comments. He urged us to get back in the car asap and start heading back over the border to Belize.

In one of the rural market towns we visited in Belize we saw members of a Mennonite community which resided in the country, we thought we were in Lancaster County in PA. It was interesting to drive around the country, not only did we see many different species of trees but also a mix of several different cultures and genetic blood lines.

As far as out intended mission, once we learned the availability of the different lumber species, Peter started negotiating pricing with the Loskots. Peter ended up making a 2nd trip to Belize to finalize arrangements for the deal and logistic for transportation. Special arrangements had to be made for shipping the lumber to the US, a process which was assisted by a maritime shipping agent in Baltimore. At that time there wasn’t a dock large enough to accommodate a container ship in Belize so I believe the containers were loaded onto barges and taken out to ships at anchor.

While Peter was heading back to Belize for the 2nd time, I stayed in Baltimore to start building and setting up the construction yard. At the time there was only a long low open shelter left over from the building of the first Pride and Minnie V. We needed a larger structure to house a lofting platform to layout the frames, tool storage, small office, and large saw house to accommodate the ship band saw.

The ship saw is a special large band saw which has large wheels that rotate the angle of the blade rather than the table tilting. This was essential for cutting angle on edges of large timbers for the ship’s frame. Since the saw’s cutting table was above reachable distance from the ground, it needed a raised platform around the saw and also a lot of room to maneuver large timbers. In addition to these structures we had to set up timber block stations for the keel of the boat to rest on. This would be the foundation for the structure of the boat to rise up from.

Once the 40’ sea containers reached the Port of Baltimore and cleared US Customs, they were delivered to the construction yard at the Inner Harbor next to the Science Center by a tractor trailer. When the doors of the container were opened, there was still the mist and smell of the tropics, along with several small tree frogs hopping out to daylight.

The lumber was packed so tight and somewhat irregular that we needed to use a chain and forklift to pull pieces out. We then had to sort the different species and make stickered stacks of lumber pieces (flitches) for selection. We would then make patterns on the lofting platform and then lay out these shapes on the flitches of lumber for cutting.

The lumber species we used in construction included:

- Santa Maria frames

- Cortex (Ipe) keel

- Bullet Tree structural members

- Machich (Black Cabbage Bark) structural members

- Mahogany rail caps, deck house & interior millwork

- Teak ship’s wheel

- W. Oak planking & mast hoops( from Maryland forests)

- D. Fir decking and spars

- Cypress frame stop waters

- Lignum Vitae deadeyes (rigging)

In Belize we also looked at Billyweb, Sapadila (chickle) and Ziricote

This whole process was an education for me in so many ways, which I think holds true for all of the crew members involved in the construction process. We learned a lot about the many species of woods, some which were very challenging to mill. There were many specialized tools we had to set up and use during the building process including a forge for steel and bronze hardware, and a large steam box to cook the W. Oak planking in order to bend to the shape of the hull.

We learned to work as a team which totaled to between 18-30 people. A good majority had come from the traditional boat world, however we had a compliment of people with varied backgrounds including a retired school superintendent, 2 people who had seen active combat in WWII, and a Marine who fought in Korea. We also had some dedicated volunteers.

This was hard work and some long days thru cold winter weather and blazing hot and humid summers in Baltimore. I think I can speak for most all the members of the building team, this was one of the best projects I have ever worked on and some of the most talented people I have ever worked with. I feel very fortunate to have had this opportunity.

Gary ‘Leroy’ Surosky

Peregrine Construction Group, LLC

March 2024